Changing behaviors within your current culture

The challenge of handwashing in foodservice is rooted in basic human behavior. If the would-be washer can see no reward, he or she becomes a non-washer; this is even true for managers. Handwashing simply becomes a matter of custom, comfort or convenience with no connection to the actual risk. The complexity of a sustainable solution results in operators attacking one barrier at a time, but a holistic approach has a much better chance of success.

Real issues abound. Barriers of language, culture, turnover, absenteeism, productivity, hand sink location, empty dispensers, skin irritation and training time frequently come up as challenges to handwashing at key moments. However, the reality is there is no measurement for a clean hand, no standards for frequency and seldom are employees disciplined for not washing their hands. These barriers actually protect the status quo and endanger the life of the customer, staff and the very business itself.

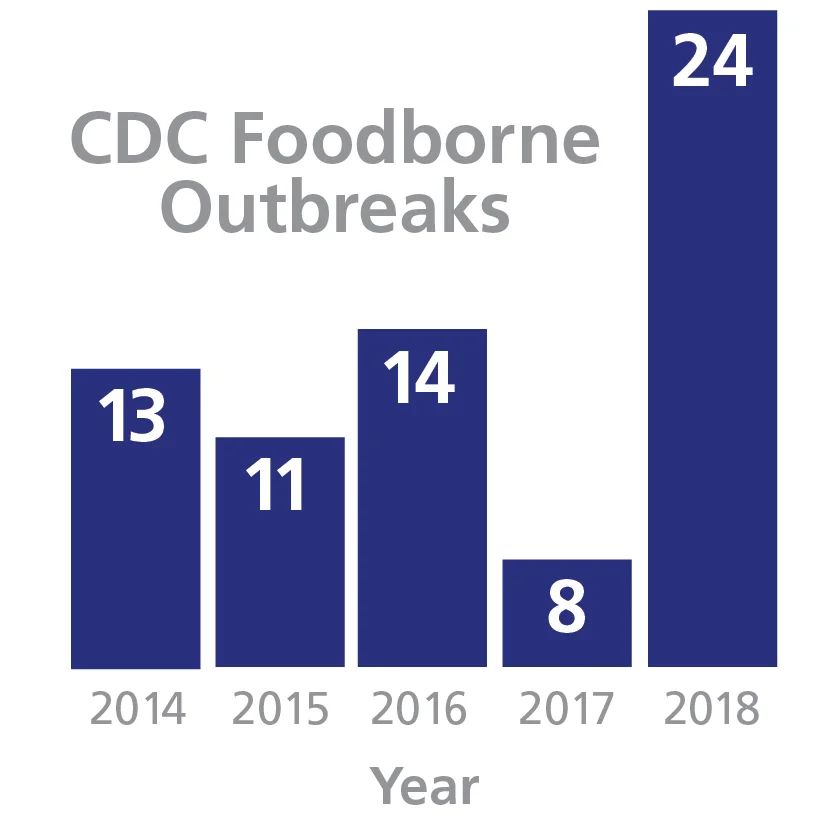

Handwashing competes with the highly valued indicators of productivity on which managers and staff are measured and rewarded. The risk of a foodborne outbreak is already high but getting much higher by virtue of the current trends in rising punitive damages and threatened executive jail time. Advancements in science like Whole Genome Sequencing (WGS) have equipped the CDC Pulse-Net labs with the capability to identify outbreaks previously missed by first-generation systems.

Measuring Handwashing

Risk management must play a larger role in fixing the time-hardened handwash behaviors. The answer is in process control for which numbers are needed -numbers to reach and sustain goals via the built-in employee Performance Review structure. The steps for a sustainable solution are to first assess the risk, set standards, set the conditions for success, train and finally monitor to motivate the needed behavior change.

The Handwashing For Life Institute has developed tools to help change handwashing behavior. All of these lead to measurement as a way to motivate and sustain hand cleanliness levels and the behaviors required.

High-touch surfaces frequently harbor pathogens. High levels of pathogens remain invisible but are more likely to cross-contaminate than those surfaces frequently cleaned and measured with either ATP or UV tracing systems. The measurement increases the cleaning frequency.

Handwashing effectiveness can be given a number by using invisible tracing lotion and scanning with a UV light to illuminate areas missed. This training method adds visual impact that helps a workforce better understand the need for a thorough wash.

A safe-level frequency of washing hands is an important standard to engage the staff in setting. The number is always imprecise, but it is reached through collaboration with peers and their managers. The most dramatic improvement in handwash frequency occurs with the addition of electronic logging of actual washes and comparing them to the employee-agreed safe level standard. In addition, some firms have developed electronic monitoring solutions to help measure and ensure compliance.

Data converts randomness to a process and drives a sustainable handwashing solution. Handwashing becomes clearly understood as a critical risk-based behavior. Now success can be calibrated, celebrated and perpetuated.